- In the world of arts and crafts, purple PVC tape has become a favorite among artists and DIY enthusiasts. Its flexibility allows it to be shaped and molded into various forms, while its adhesive strength holds materials securely in place. From creating intricate designs on canvas to adding a pop of color to scrapbooks, this tape adds a unique dimension to creative projects.

- Furthermore, colored PVC tape is an essential tool for event planners and decorators. The tape can be used to create temporary markings, decorations, or signage for special events such as parties, weddings, or conferences. Its adhesive backing allows for easy installation and removal without leaving behind any residue.

- Installing floor marking tape is a straightforward process that typically involves cleaning the area where the tape will be applied and then applying the tape using a roller or squeegee. Once in place, the tape should be allowed to fully adhere to the surface before walking on it or using heavy machinery over it.

coloured electrical tape. When wrapped around wires and cables, it creates a barrier that prevents moisture, dirt, and other contaminants from penetrating and causing harm. This is particularly useful in areas where the wires are likely to be subjected to physical wear and tear, such as in industrial settings or on construction sites.

coloured electrical tape. When wrapped around wires and cables, it creates a barrier that prevents moisture, dirt, and other contaminants from penetrating and causing harm. This is particularly useful in areas where the wires are likely to be subjected to physical wear and tear, such as in industrial settings or on construction sites.Linerless Insulating Rubber Tape

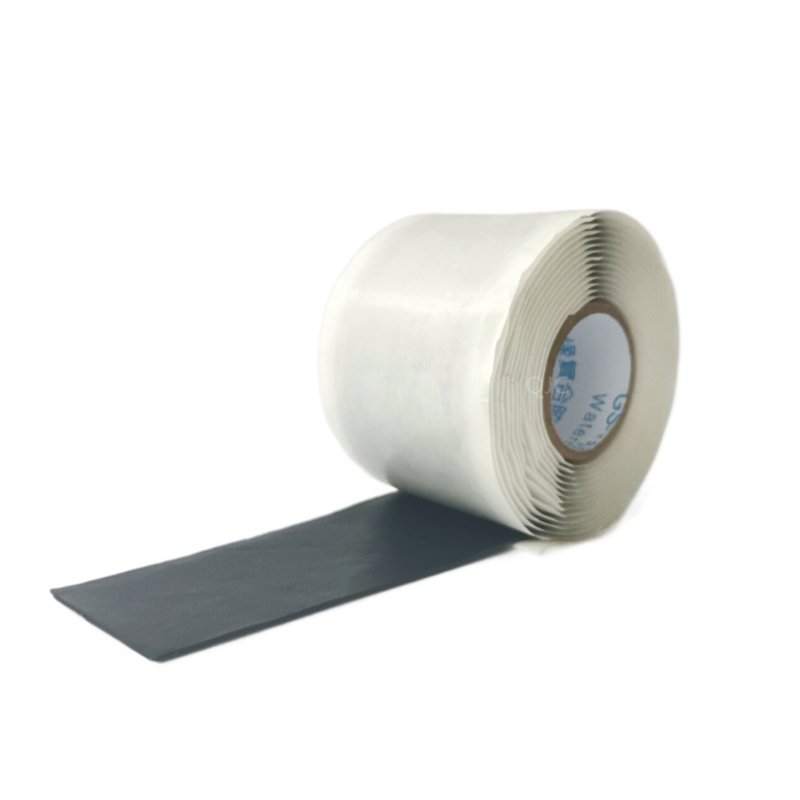

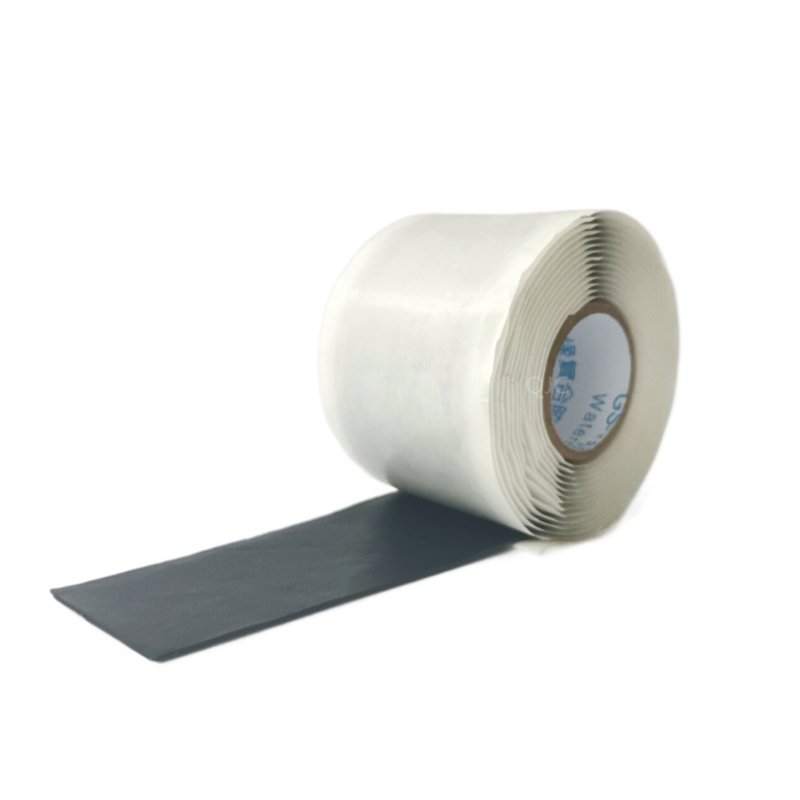

In the world of DIY projects and home repairs, few products have gained as much notoriety and acclaim as Flex Tape. Marketed as a super-strong adhesive tape that can seal, bond, and repair virtually anything, Flex Tape truly lives up to its reputation. In this article, we will take a closer look at Flex Tape, focusing on the white variant in 4-inch by 5-foot dimensions, exploring its uses, benefits, and overall effectiveness.

liquid rubber electrical insulation. It is highly durable and can withstand harsh environmental conditions without degrading or losing its insulating properties. This makes it an ideal choice for outdoor applications or areas where exposure to chemicals or sunlight is a concern.

liquid rubber electrical insulation. It is highly durable and can withstand harsh environmental conditions without degrading or losing its insulating properties. This makes it an ideal choice for outdoor applications or areas where exposure to chemicals or sunlight is a concern.You may also choose a tape color based on branding or personal preferences. If your company uses certain colors in its advertising, using those same colors for your custom branded tape will improve your brand recognition. If you print tape with a stylized logo, you should select a background color that will contrast well with the logo design. And of course, you are free to choose a tape color purely because you like how it looks.

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets diall self amalgamating tape. Celebrating minor victories along the way is essential, similar to acknowledging the successful mends made by the tape.

diall self amalgamating tape. Celebrating minor victories along the way is essential, similar to acknowledging the successful mends made by the tape.Polyethylene Film Tape 9 Mil Rubber

One of the primary factors affecting the price of insulation tape is the quality of the materials used in its manufacturing. Insulation tapes can be made from various substances, including PVC (Polyvinyl Chloride), rubber, or cloth. Generally, PVC insulation tapes are the most common and are widely used due to their cost-effectiveness and reliability. However, higher-quality materials, such as rubber-based adhesives or more robust cloth tapes, may come at a premium. The complexity of the material and its ability to withstand heat, cold, or moisture can significantly influence the price.

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations yellow and green electrical tape.

yellow and green electrical tape.